Products

Search, filter and compare our products

Toray MicroPly™ SC8020A

MicroPly SC8020A low-density unsupported epoxy syntactic core. SC8020A offers reduced processing, a one-shot cure, the ability to anchor inserts or fastenings, and increases the opportunity to consider lightweight, thin walled composite sandwich structures

Toray MicroPly™ SC72A

Toray MicroPly SC72A is a low-density unsupported epoxy syntactic core. Offering reduced processing, a one-shot cure, the ability to anchor inserts or fastenings & increases the opportunity to consider lightweight, thin-walled composite sandwich structures

Toray MicroPly™ EF8020

Toray MicroPly™ EF8020 is a modified, high-strength, structural epoxy film adhesive for honeycomb core and laminate bonding. EF8020 is compatible for co-cure with Toray’s 8020 prepreg and SC8020 syntactic core.

Toray Cetex® TC960

Toray Cetex® TC960 is a polypropylene (PP) composite designed for applications requiring high impact resistance, but where cost is a factor. The impact toughness of TC960 makes it ideal for use in truck bodies, vehicles and vehicle enclosures.

Toray Cetex® TC915 New

Toray Cetex® TC915 is a thermoplastic composite using a high-performance polyamide matrix resin. This product provides exceptional mechanical properties higher than typical polyamide-based composites and Nylon materials.

Toray Cetex® TC910

Toray Cetex® TC910 is a high strength thermoplastic composite using a polyamide 6 (PA6) matrix resin designed for applications such as automotive and transportation. It provides good heat distortion temperatures and excellent solvent resistance.

Toray AmberTool® HX56

Toray AmberTool® HX56 is an epoxy composite tooling prepreg. After a suitable post cure, an end use temperature of 180ºC (356ºF) is achieved. Toray AmberTool® HX56 achieves an excellent surface finish for small to medium sized autoclave tooling.

Toray AmberTool® HX42

Toray AmberTool® HX42 is an epoxy composite tooling prepreg. After a suitable post cure, an end use temperature of 210°C (410°F) is achieved. Toray AmberTool® HX42 has proven pedigree in aerospace tooling.

TC750 New

Toray TC750 is a toughened epoxy component prepreg developed for structural applications within high performance automotive. TC750 facilitates curing from 80°C (176°F) to 180°C (356°F) and can be pre-impregnated into a range of fiberand fabric types.

TC420

TC420 is a flow controlled cyanate ester prepreg, toughened to resist microcracking. TC420 is ideal for out of autoclave large structures in ultra high temperature applications. It is easy to process and yields a low void content under vacuum bag only.

TC346 New

Toray TC346 is a high temperature epoxy component prepreg developed for structural applications within Formula 1 and high performance automotive.

RS-1

RS-1 is an epoxy prepreg which provides an excellent balance of mechanical properties, toughness and modulus. RS-1 has been evaluated and qualified in areas ranging from marine to aerospace. RS-1 is also available in a 80°C curing formulation.

Nomex® Honeycomb Core—Aerospace Grade

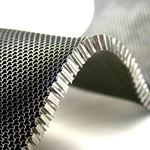

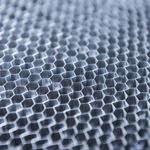

ANA aerospace grade Nomex® honeycomb core is manufactured from Nomex® paper sheets, coated and bonded together with a phenolic resin. It offers high strength to weight properties at relatively low cost and, FST performance where required.

Flex-Core - Aluminum Core—Aerospace Grade

Flex-Core® aluminum aerospace grade honeycomb core is available in corrosion resistant 5052 and 5056 alloy. It has unique cell configurations that permit small radii of curvature without deformation of the cell walls or loss of mechanical properties.

E760

E760 is a highly toughened epoxy component prepreg with exceptional high temperature performance. E760 has been designed for use in mechanically demanding structural applications exposed to elevated temperature environments e.g. Formula 1.

E750

E750 is a toughened epoxy component prepreg developed for structural applications within Formula 1 and high performance automotive. E750 allows curing from 80°C (176°F) to 180°C (356°F) and can be impregnated into a range of fiber and fabric types.

E745

E745 is a 135°C (275°F) cure toughened epoxy component prepreg. E745 has been developed for impact structures and other mechanically demanding structural applications. E745 can be impregnated into a range of fiber and fabric types.

E732 New

E732 is a snap cure toughened epoxy resin matrix optimized for press curing (compression molding) prepreg applications. With a cure time of 4 minutes at 160°C (320°F), an onset Tg of 170°C (338°F) is achieved.

E726

E726 is a 120°C (248°F) cure toughened epoxy prepreg with controlled flow. E726 is designed for use within medical and industrial applications. E726 is compatible for co-cure with EF72 film adhesive and Amlite SC72A syntactic core.

E722

E722 is a 120°C (248°F) cure toughened epoxy component prepreg. E722 is designed for structural applications in motorsport and marine industries and, a wide range of engineering applications.

E721-FR

E721-FR is a 120°C (248°F) cure modified epoxy prepreg of medium viscosity. E721-FR offers excellent structural properties, flame retardancy and exceptional toughness allowing direct lamination to honeycomb without the use of a film adhesive.

E720

E720 is a 120°C (248°F) cure toughened epoxy prepreg. E720 offers excellent adhesive properties, allowing direct lamination to honeycomb without the use of a film adhesive.

Aluminum Honeycomb Core—Commercial Grade

Toray’s aluminum commercial grade honeycomb core is manufactured from corrosion-resistant 3003 alloy foil. It offers high strength-to-weight properties at relatively low cost, particularly suitable as a shear carrying core in sandwich panel structures.

8020-FR

8020-FR is a modified epoxy component prepreg offers excellent structural properties, flame retardancy, and toughness. The Toray 8020-FR resin system has been developed to offer a long out life and flexible cure schedules from 70–120°C (158–248°F).

8020

8020 toughened epoxy component prepreg offers an excellent balance of mechanical properties and excellent surface finish. The Toray 8020 resin system has been developed to offer a long outlife and flexible cure schedules from 70-130°C (158-266°F).

- 1

- 2

Need more information?

At Toray our goal is your success. If you have any questions or would like to learn more, please contact us.

Toray Advanced Composites UK

Need more information?

At Toray our goal is your success. If you have any questions or would like to learn more, please contact us.

.jpg?w=150&h=150&q=80&action=crop)

Toray Advanced Composites USA

.jpg?w=40&h=40&action=crop)