Composite Tooling Materials and Support from Toray

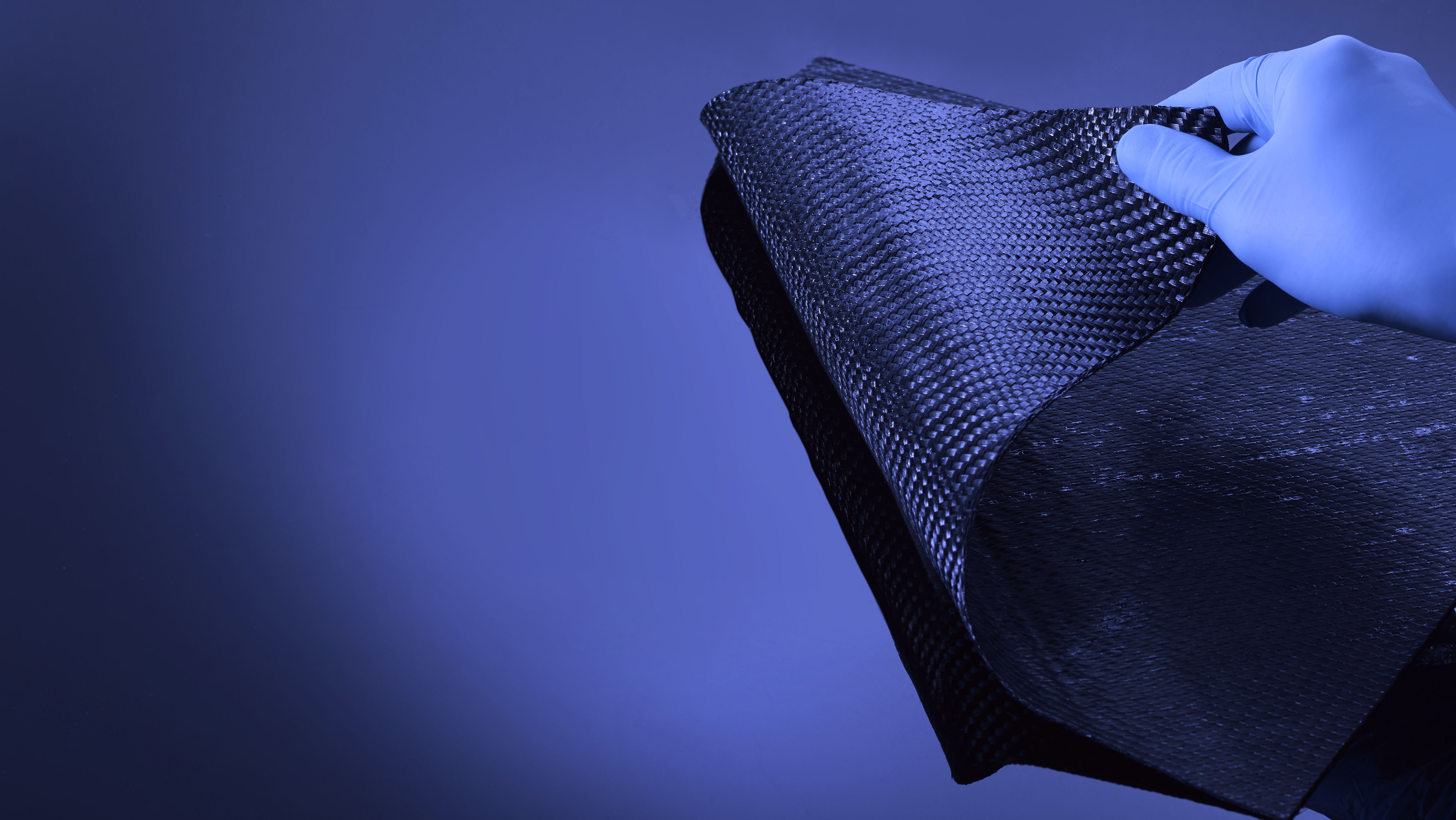

The Toray AmberTool® series of tooling prepregs have become the trusted benchmark products across the composites industry for over 20 years. They have an excellent reputation for reliability and deliver a cosmetic surface finish.

Alongside our composite materials, we offer training, design, and technical support to support you with your next tooling project.

Resources

Toray AmberTool® Tooling Prepreg Processing Guide

Get PDF by email

Toray Guide to Composites—Volume One

Request print copyWhy Use Toray AmberTool® Tooling Prepregs?

Surface Quality

Tools made with Toray AmberTool® materials achieve a highly accurate and dimensionally stable finish. Combined with very low porosity, this quality solution provides longevity of tool life with exceptional aesthetics for composite component production.

Handleability

Rapid room temperature lay-up is a major advantage for fast-moving assembly operations. Toray Ambertool® solutions offer improved handling for both simple and complex geometries, reducing lay-up time and ultimate tooling cost.

Design Freedom

We know you need flexibility in a product to meet your design specifications. The Toray AmberTool® family of tooling prepregs offers Tgs from 162°C to 213°C, out life up to 30 days, and cure from as low as 40°C, offering you significant design freedom.

Composite Tooling

Toray has a Toray AmberTool Processing Guide available on our website in the Resources section, under Processing Guides. Plus we have tooling experts on staff to answer any questions you may have.

Tooling prepregs are typically chosen by first considering the Tg of the tool to ensure it is capable of withstanding the typical cure temperature of the part. Ideally, one would like to see the Tg of the tool to be at least 10°C / 50°F higher than the cure of the part.

Second, a critical factor to consider is the processing temperature of the tooling board master. Since master materials are typically low Tg, it is critical that during the initial cure of the tooling prepreg master that it stays dimensionally stable. If the tooling master has a Tg stated maximum, then one would not want to exceed this during the cure of the tooling prepreg. Also, remember that tooling prepregs must undergo a final free-standing high temperature post cure to be able to withstand multiple part cure cycles and maintain long term durability.

Another consideration is the size of the tool and the outlife of the tooling prepreg selected. The outlife must be greater than the time taken to laminate and cure the tool.

Finally, will the tool deliver the quality of parts required for the duration of the project? The Toray AmberTool® HX-series of tooling materials have delivered expected life for decades. Typically, a standard life for a composite tool is greater than 250 cycles.

Yes, tools as large as 40 meters long x 3 metres wide (130 x10 foot) wide have been fabricated with the Toray AmberTool® HX series of tooling materials. Tools may be net molded or machine finished to final part dimensions. In net molding, a solid master is prepared to the exact part shape, with allowance made for thermal expansion. From this master, the final composite tool is molded.

In higher temperature or very large tools, the final tool may represent an oversized part shape and it is then machined to the exact size. This is commonly done for high temperature tools where the final cure temperature may create CTE distortions or in very large tools where final dimensional accuracy is more critical.

It is possible to cure and consolidate the Toray AmberTool® HX-series of prepregs with vacuum only pressure, but it is not recommended.

However, its highly likely that an increase in voids will occur. These can have a detrimental effect on surface finish and tool pressure integrity. For this reason, we do not recommend non autoclave processing of these products. For further advice please contact your technical service team.

Typically, a low temperature initial cure is carried out on a tooling board master. When this method is used, to maintain dimensional accuracy it is important to minimize thermal expansion. As such, Toray AmberTool® HX-series tooling prepregs are cured initially at a low temperature on the master, then they undergo an evenly-supported post-cure to reach their ultimate Tg.

Need more information?

Please get in touch with our tooling experts to learn more about how Toray can help you with your next tooling project.

Need more information?

Please get in touch with our tooling experts to learn more about how Toray can help you with your next tooling project.

.jpg?w=40&h=40&action=crop)

Newsroom

Newsroom  Product Explorer

Product Explorer  Data Sheets

Data Sheets  Contact

Contact

.jpg?w=16&h=9&q=1)

.jpg?w=16&h=9&q=1)