Products

Search, filter and compare our products

Toray MicroPly™ TC310

Toray MicroPly™ TC310 is a toughened epoxy film adhesive with excellent mechanical properties and toughness. It is ideal for honeycomb or laminate bonding and may be cured in either autoclave or vacuum bag processing.

Toray MicroPly™ TC263

Toray MicroPly™ TC263 is a toughened, high peel strength, structural epoxy film adhesive for honeycomb core and laminate bonding. It may be used in low pressure vacuum only, out-of-autoclave processes or in autoclave processes at 15 psi.

Toray MicroPly™ TC248SF

Toray MicroPly™ TC248SF is an epoxy composite surfacing film, allowing a smooth, paintable surface from tooling or, a thin-skinned honeycomb stiffened composite structure. It may be cured under vacuum only pressure or under low autoclave pressure.

Toray MicroPly™ SC72A

Toray MicroPly SC72A is a low-density unsupported epoxy syntactic core. Offering reduced processing, a one-shot cure, the ability to anchor inserts or fastenings & increases the opportunity to consider lightweight, thin-walled composite sandwich structures

Toray MicroPly™ EX-1516

Toray MicroPly™ EX-1516 cyanate ester film adhesive which has been formulated for low moisture absorption and / or low dielectric constant and loss applications. It provides strength and toughness when bonding solid, honeycomb or foam core structures.

Toray MicroPly™ ES72A-2

MicroPly™ ES72A-2 low-density, expanding, unsupported, epoxy syntactic core. Offering reduced processing, a one-shot cure, the ability to anchor inserts / fastenings and, the opportunity to consider lightweight, thin walled composite sandwich structures.

Toray Cetex® TC940

Toray Cetex® TC940 is a high strength semi- crystalline polyethylene terephthalate (PET) thermoplastic composite designed for applications requiring high impact strength at good value, such as recreational equipment.

Toray Cetex® TC1000 Design

Toray Cetex® TC1000 Design is a cost-effective, high-end thermoplastic composite, utilizing the amorphous PEI polymer for outstanding toughness and an inherently outstanding fire, smoke, and toxicity performance (< 15/15 OSU).

Toray Cetex® MC1322 New

Toray Cetex® MC1322 PEKK is a thermoplastic BMC based upon TC1320 UD tape using high strength fibers in lengths of up to 25.4mm (1"). MC1322 allows complex shapes to be made with varying wall thickness, integrated ribs and reinforcing structures.

Toray AmberTool® HX42

Toray AmberTool® HX42 is an epoxy composite tooling prepreg. After a suitable post cure, an end use temperature of 210°C (410°F) is achieved. Toray AmberTool® HX42 has proven pedigree in aerospace tooling.

TC890

TC890 is a very high temperature polyimide prepreg utilizing PROOF 900HT resin system. It has a service temperature capability up to 427°C (800°F). It displays exceptional toughness, superb low dielectric loss properties and is thermally stable.

TC750 New

Toray TC750 is a toughened epoxy component prepreg developed for structural applications within high performance automotive. TC750 facilitates curing from 80°C (176°F) to 180°C (356°F) and can be pre-impregnated into a range of fiberand fabric types.

TC410

TC410 cyanate ester prepreg achieves extremely low moisture absorption and high conversion levels. TC410 is designed specifically for radomes and satellite structures, providing good resistance to radiation, low microcracking and, low dielectric and loss.

RS-8HT

RS-8HT is a BMI resin which provides excellent elevated temperature properties and processability. RS-8HT has been evaluated and qualified in the areas of satellite and airframe / missile structures.

RS-3/RS-3C

RS-3 is a modified cyanate ester prepreg, providing a good balance between toughness and high temperature/wet performance. RS-3 is qualified in satellite, airframe/missile and, radome structures. RS-3C is a controlled flow vacuum bag only cure version.

RS-16

RS-16 is a two-part low viscosity cyanate ester RTM resin for wet winding, RTM and VARTM processing. RS-16 is intended for lower temperature exposure and is an ideal system when used with different materials limiting the upper cure temperature.

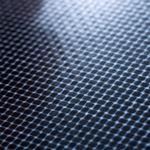

Nomex® Honeycomb Core—Aerospace Grade

ANA aerospace grade Nomex® honeycomb core is manufactured from Nomex® paper sheets, coated and bonded together with a phenolic resin. It offers high strength to weight properties at relatively low cost and, FST performance where required.

EX-1545

EX-1545 is a toughened two-part cyanate ester resin with extremely low viscosity at room temperature, allowing RTM to take place with minimal resin heating. This facilitates mold filling time for difficult and / or large RTM’d structures and reduces waste.

EX-1515

EX-1515 cyanate ester prepreg provides optimal mechanical properties, high radiation resistance, microcracking resistance, low moisture absorption / low outgassing while retaining toughness, a low 244°F (118°C) stress-free temperature and long out time.

E722

E722 is a 120°C (248°F) cure toughened epoxy component prepreg. E722 is designed for structural applications in motorsport and marine industries and, a wide range of engineering applications.

E721-FR

E721-FR is a 120°C (248°F) cure modified epoxy prepreg of medium viscosity. E721-FR offers excellent structural properties, flame retardancy and exceptional toughness allowing direct lamination to honeycomb without the use of a film adhesive.

BTCy-1

BTCy-1 is a 177°C (350°F) curing cyanate ester prepreg and is an industry standard for use on satellite structures and radomes.

BT250E-6

BT250E-6 resin system is a 121°C (250°F) cure epoxy with excellent strength and stiffness. It provides an outstanding surface finish under vacuum bag/oven cure. BT250E-6 has an FAA-accepted database on carbon IM-7 UD tape, S2-glass, and AS-4C plain weave.

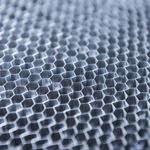

Aluminum Honeycomb Core—Aerospace Grade

Toray’s aluminum aerospace grade honeycomb core is available in corrosion resistant 5052 and 5056 alloys. It offers high strength-to-weight properties at relatively low cost; particularly suitable as a shear carrying core in sandwich panel structures.

8020-FR

8020-FR is a modified epoxy component prepreg offers excellent structural properties, flame retardancy, and toughness. The Toray 8020-FR resin system has been developed to offer a long out life and flexible cure schedules from 70–120°C (158–248°F).

Need more information?

At Toray our goal is your success. If you have any questions or would like to learn more, please contact us.

Need more information?

At Toray our goal is your success. If you have any questions or would like to learn more, please contact us.

.jpg?w=40&h=40&action=crop)

Newsroom

Newsroom  Product Explorer

Product Explorer  Data Sheets

Data Sheets  Contact

Contact