Success Stories

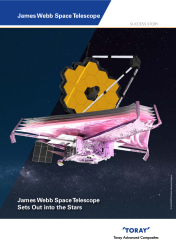

James Webb Space Telescope Sets Out into the Stars

December 2021 marked the beginning of the historic launch of the James Webb Space Telescope (JWST), the most complex and powerful telescope designed, greatly expanding mankind’s vision among the stars. Toray Advanced Composites was chosen as the ideal composite material solution partner by Northrop Grumman Aerospace for all three major components of the James Webb Space Telescope; the Optical Telescope Element (OTE), the Integrated Science Instrument Module (ISIM), and the Spacecraft Element (SCE).

Unfolding the Universe

Twenty-five years ago, curiosity overcame the scientific community. The National Aeronautics and Space Administration (NASA), European Space Agency (ESA), and the Canadian Space Agency (CSA) unveiled the most ambitious space science project of the 21st century thus far to unfold the universe and learn more about the formation of stars, planets, and the creation of the very first galaxies in the early universe. The task involved launching the largest advanced telescope ever sent to space and positioning it 1.5 million km (930,000 miles) from Earth to orbit the Sun at the second Lagrange point (L2). This is four times the distance to the moon, and it will keep JWST in line with the Earth as it captures near-infrared light from space.

"With an optimized balance of mechanical properties and features, program scientists and engineers ensured the telescope will deliver precise images that are over 100 times more defined than the HST and finally helping to answer the age-old question of how the universe began."

In the past decade, JWST, the successor to the Hubble Space Telescope (HST), has undergone multiple instances of strenuous testing and redesigns, and overcame a global pandemic to finally leave home for the long trip into space. Among the design challenges was choosing the best composite material to endure the extreme environment of space. Backed by over 30 years of space flight materials heritage, Toray has been a trusted collaborator with several foremost aerospace leaders on many projects, including the Mars Perseverance Rover, Mars Ingenuity helicopter, the Kepler Space Telescope, and nearly every satellite launched in the western world.

“We are honored to be included as the fiber and prepreg material supplier for JWST and I can’t think of a program more well-suited to meet Toray’s core mission of contributing to society through the creation of new value with innovative ideas, technology, and products,” says Eric Howard, Aerospace Sales Director of Toray Advanced Composites. “I think nearly all humans are inspired by the night sky on grand display, even to the unaided eye. As we extensively learned from Hubble, JWST is certain to enhance our knowledge of the heavens and is certain to foster curiosity and inspire the next generation of explorers, engineers, and scientists.”

Innovation from Top to Bottom

JWST is a modern-day engineering marvel, sporting the most advanced technology to make a complex trip through space appear as simple as a stroll through the park. The sophisticated innovations needed to make this space trip mission achievable was enabled through the collaboration of scientific and engineering teams with the most advanced, space-proven materials at their disposal that are tough, strong, stiff, and lightweight, yet capable to withstand the severe aerodynamic, thermal, and kinematic stresses from launch to orbit around the sun. All this while maintaining tolerances of only millionths of an inch in order to assure flawless performance on station. Toray RS-3 and RS-3C composites utilitizing ultra-high modulus TORAYCA® M60J carbon fiber exhibit outstanding mission-critical properties, including:

- Exceptional toughness and resistance to microcracking

- High glass transition temperature (Tg)

- Low coefficient of moisture expansion (CME)

- Low coefficient of thermal expansion (CTE)

- Low outgassing

- Outstanding tolerance to radiation exposure and thermal cycling

The TORAYCA® M60J, from Toray Composite Materials America, Inc., is a high modulus fiber with enhanced tensile and compressive strength. It is the highest modulus PAN-based carbon fiber in the market, with a tensile modulus of 85.3 Msi.

Toray All Around

The Deployable Tower Assembly (DTA), a subsection to the OTE, is widely considered a critical technical upgrade from its predecessor, the Hubble Space Telescope (HST), for its origami-style of folding for stowing the telescope sections in to the Ariane 5. Once in space, the DTA extends 1.5 meters and lifts over 3,311 kilograms (7,300 lbs.), to deploy the primary mirror, secondary mirror array, and backplane equipment.

Not only was JWST constructed with high-tech tools, but many of JWST’s ground-breaking innovations lie within the finer details. The DTA was intentionally designed to provide a gap between the spacecraft, sunshield, and telescope sections in order to minimize vibrations and provide thermal isolation between the scientific instrumentation and warmer electronics and propulsion systems. This ensures the mirrors and sensors are at the coldest temperatures possible, a necessity to enable infra-red detectors to capture the most light and render the sharpest images possible.

Mission success – ability to capture a clear image of incoming infrared light – also hinges critically on the stability of the DTA structure itself. The DTA will keep the telescope stable to within an incredible 38 nanometers while simultaneously tolerating extreme temperatures from -243°C to -208°C (-406°F to -343°F). With an optimized balance of mechanical properties and features, program scientists and engineers ensured the telescope will deliver precise images that are over 100 times more defined than the HST and finally helping to answer the age-old question of how the universe began.

Learn more about our materials for space