Success Stories

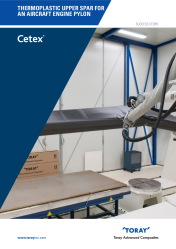

Thermoplastic Upper Spar for an Aircraft Engine Pylon

Nijverdal, The NetherlandsThis project was completed under the company name TenCate Advanced Composites, prior to our acquisition by Toray Industries and name change to Toray Advanced Composites in 2019.

Automated Production of Large and Thick Thermoplastic Composite Aircraft Parts

As part of a Dutch innovation program called TAPAS 2 (Thermoplastic Affordable Primary Aircraft Structures 2), NLR has developed a technique to manufacture large and thick thermoplastic composite parts using Advanced Fiber Placement (AFP).

The part, made using TenCate Cetex® TC1320 C/PEKK uni-directional tape, is 6-meters long and 28-millimeters thick. Using a pylon upper spar made of composite instead of steel allows aircraft manufacturers to reduce production costs and weight, and thus save on fuel consumption of aircraft.

TenCate Cetex® TC1320 C/PEKK uni-directional tape

- Resistant to solvents and chemicals

- Good impact resistance and toughness

- Low moisture uptake, good hot/wet strength retention

- Flame retardant

- Good compression after impact performance

TenCate Cetex® C/PEKK uni-directional tape is suitable for automated fiber placement, which combined with excellent mechanical properties, enables the efficient automated production of a high-performance aerospace structure.

Using its advanced fiber placement machine, NLR laid elongated thermoplastic tracks alongside each other an subsequently “fused” them to form a pylon upper spar in Fokker’s autoclave. By using AFP, the “buy-to-fly ratio” of the material is high, since locale build-ups can be made without scrap edges.

Recyclable

The manufacturing of a composite pylon upper spar is more sustainable than making a structure that contains steel. The cutting leaves little residual material, and what does remain is recyclable. The pylon upper spar itself can also be completely shredded and reused at the end of its service life. The technique devised by NLR is also suitable for other aircraft parts, such as wing spars, stabilizer spars, and floor beams, and there are also applications outside the aviation sector.